The Right People

Great Boiler Operators are the Recipe for Growth, Change, and Continuous Improvement

In today’s competitive landscape, facility managers and owners are being asked (or expected) to “do more with less” and accomplish that objective without falling short of expectations. A large majority fall short because they fail to focus on “greater results with less effort”. Working smarter, efficiently, and effectively are the outcomes of a focus on programs and procedures. It’s a strive for continuous improvement. Why are facilities dealing with unnecessary corrective maintenance, inability to manage overtime, extended outages, reduced efficiency, and general low morale? This is not an easy question to answer. So many variables have an impact on answering this industry issue and asking for help can go a long way. The right partnership can provide the right people resources for any organization — an enabler for positive change.

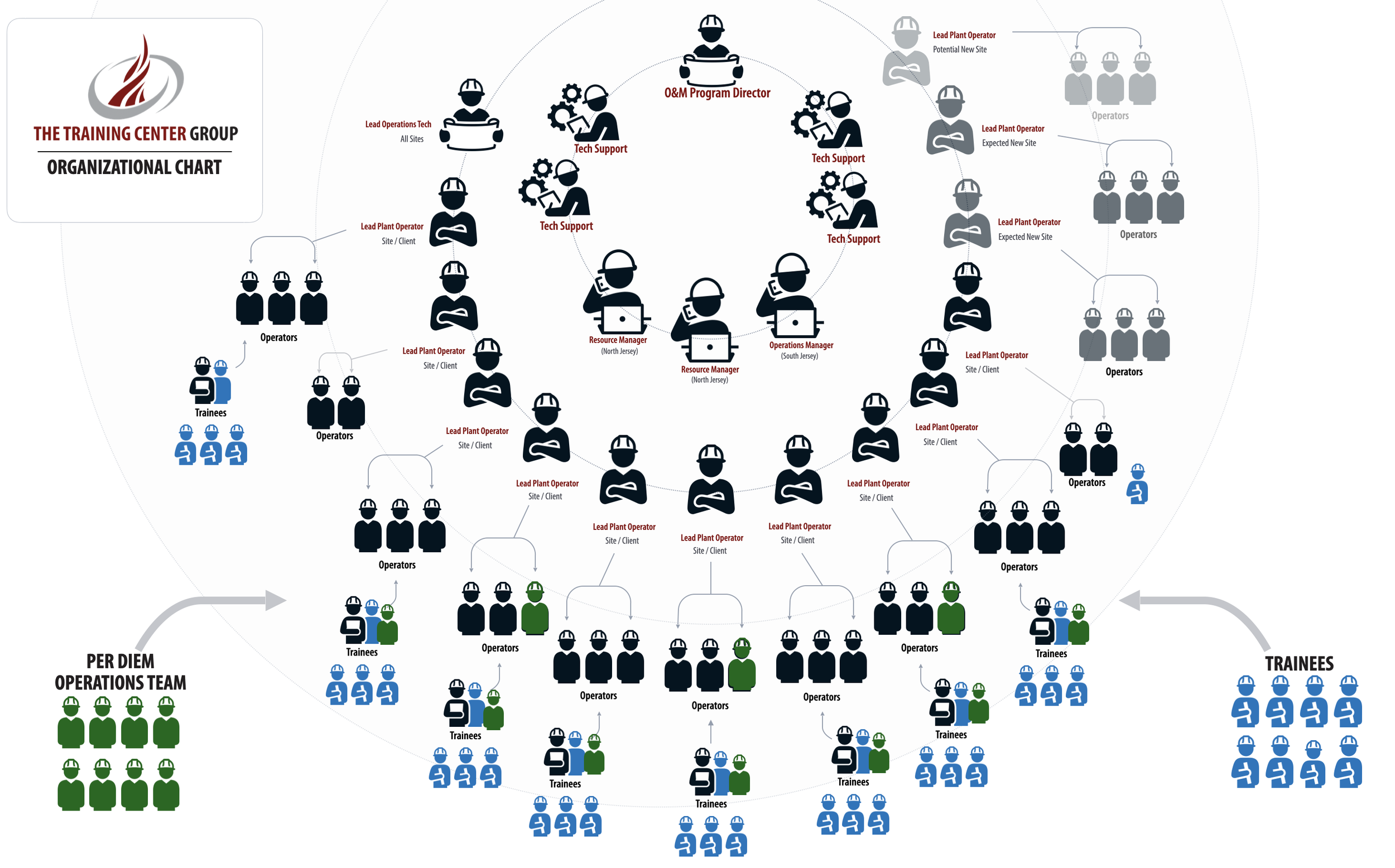

Our solution is providing top rated boiler services and maintenance through full-time boiler staffing and support from The Training Center Group. We network with a large group of leading licensed professional boiler operators and plant operators that serve clients and bring the best O&M practices to all our staffed facilities.

In facilities that desire and require change, oversight of this change is crucial to accomplish your facility needs relating to safety, efficiency and reliability. An advantage from a large network is bridging the industry’s best practices across facilities, sharing production methods, employing best practices, ideas, and keeping a student mentality (TSM) in order to inspire and empower operators. Learning must be a constant part of a boiler operator's core job. It is a step in building an individualized multi-skilled workforce and The Training Center Group can help you expedite that journey. Any change requires time and that time is an investment into future security, safety, and reliability of the facility. Moreover, this all reduces unnecessary, costly corrective maintenance, and by itself, can pay for various short term expenses. The Training Center Group brings “The Right People” approach to staffing operations for stationary engineers.

Those who value both efficient productivity and knowledge seek to investigate the safer and economic way to complete tasks. This is a combination of taking lessons learned and applying them in a continuous learning cycle by refinement of procedures and practices.

The Training Center Group operators come from a training strategy which works and is made up of the following:

Clear learning objectives,

Essential soft skill training (without this, everything falls apart),

Organized and structured training requirements,

Hard skill training,

Site-specific implementation plans with enhanced training programs,

Consistent performance assessments.

Subjects that we specialize in for the boiler operator jobs include the following:

High pressure and low pressure steam and heating boilers, HVAC / Chillers, turbines,

Air compressors, pumps, generators, and auxiliary equipment,

Preventative maintenance and troubleshooting for powerhouse and power plant equipment,

Boiler maintenance tasks including boiler water chemistry, interlock testing, regulatory compliance, rounds, logs, and all associated mechanical equipment.

The Training Center Group has the advantage of its affiliated training company — The Training Center — to help implement the various factors that make up an efficient training program, including the following factors:

WHO: Make sure individuals trained are prepared to take on new learned objectives; a cost effective approach is to focus on how individual operational performance will impact team performance.

WHEN: Plant schedules require continuous service, after hours at additional costs, and various other factors weigh on a facility managers ability to do this at a reasonable cost. The Training Center Group has found the answer to be a combination of in-person and remote learning while on watch and testing competency of learning objectives essential to cost effective operation.

WHERE: At the facility or away? We generally find on-site the best available option, as long as distractions are managed.

WHOM: Having the right training is paramount in the process of having a world-class continuous learning experience within your organization. Consultants, colleges, or specialized training centers could be an answer…or just wasted time.

HOW: Online and on-the-job training, lecture, and home study. Combination is the right “best practice” when a training program is developed properly.

QUANTITY: An established standard, how it is evaluated, and when one accomplishes the learning objective. Tracking and controlling is indispensable. This sets goals for team members which feeds into the culture of learning as a part of everyday work life.

A world class operation is nothing more than an extension of great operators. Without great operators, there can be no great operation. In a high pressure boiler room, the investment in great people is an investment in your boiler plant as a whole.